The MTTR and the MTBF are two of the most important key performance indicators in maintenance. We will explain what the MTTR is, how to calculate the MTTR, and how to improve it. In the end, don’t forget to download our guide to reduce reactive maintenance with 8 concrete steps.

MTTR Definition

MTTR stands for Mean Time to Repair. It’s also known as the Mean Reactive Maintenance Time, and it represents the average time needed to repair a failure, returning the piece of equipment to a fully functional state.

What does the MTTR mean?

The MTTR is an indicator of maintainability (how easily a piece of equipment can be repaired). A higher Mean Time to Repair may indicate that replacing a given asset is cheaper or preferable to repairing it. On the other hand, a lower MTTR may suggest “run-to-failure” is not the worst option for that asset.

However, a high MTTR may also hint at inefficiencies. Perhaps you’re taking too long to take action, or you should store more spare parts for the equipment in question. Knowing how to reduce the MTTR is essential to avoid or minimise inactivity and the harm this may cause to your business.

How to calculate the MTTR

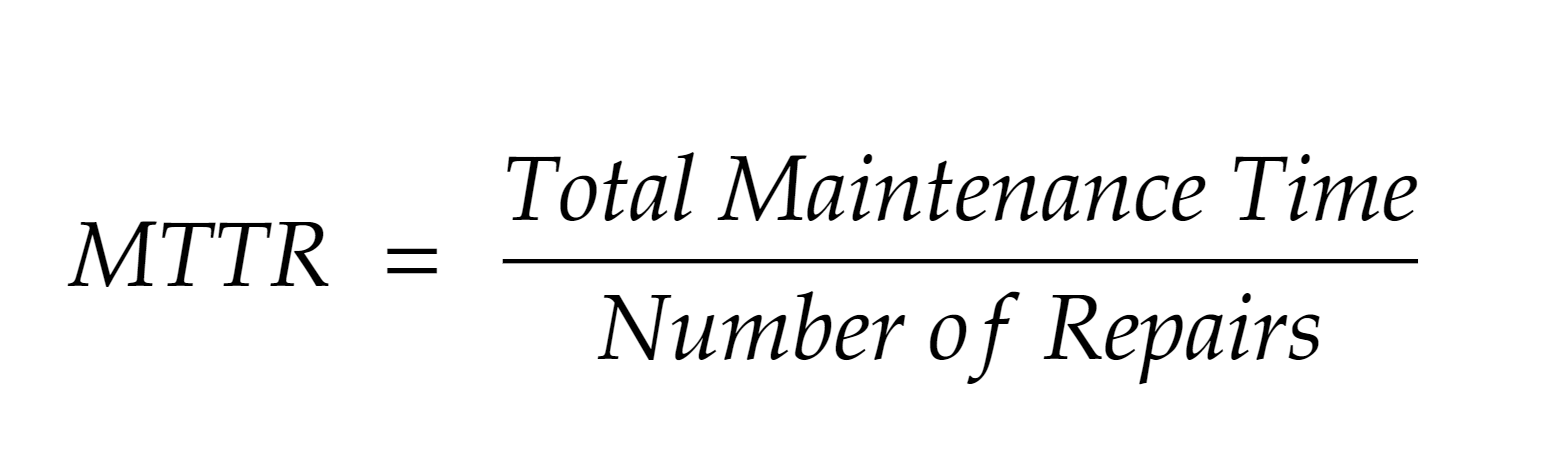

To calculate the MTTR, divide the total reactive maintenance time during a given period by the number of reactive maintenance actions performed.

📌 MTTR formula

For the MTTR calculation, “total maintenance time” is “total reactive maintenance time”, e.g. the total time spent with unplanned maintenance. The result is usually represented in hours.

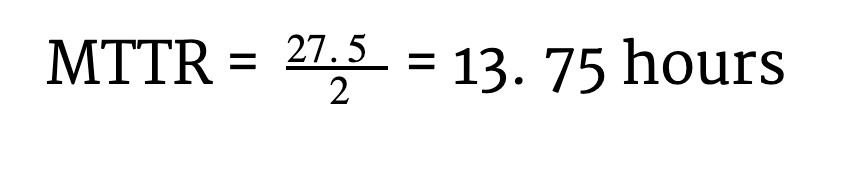

📌 MTTR calculation example

Suppose you have a vending machine working 24/7 whose panel stopped working at 16h30 and was fixed by a technician at 20:00. Later on that week, the door was stuck and it didn’t work for the whole day. What’s the MTTR in this case?

- Total maintenance time: 27. 5 (3.5 during the first failure; 24 hours during the second)

- Number of repairs: 2

📌 MTTR Standard Value

Since the Mean Time to Repair can vary considerably from industry to industry, there is no “gold standard”. However, it’s good to keep in mind that a repair should be done in under 5 hours.

📌 Mean Time to Repair vs Mean Time to Resolve

It is worth noting that the total reactive maintenance time (and therefore, the Mean Time to Repair) can range from the discovery of the failure to the actual moment the reparation works start. This includes the time for identification, notification, acknowledgement and diagnosis of the failure. But, generally, lead times for parts or other Administrative or Logistic Downtime (ALDT) are not included in the MTTR calculation.

When it incorporates all of these other steps, MTTR means Mean Time to Resolve, Mean Time to Recovery, or Mean Time to Restore.

For example, if we were talking about a digital system, the failure might be repaired before service or access to data is fully restored to all users. To avoid confusion and miscommunication, it’s important to include an explicit definition of the MTTR in maintenance contracts.

💡 Availability Calculation using the MTTR

MTTR is not just an indicator of maintainability. Here’s how to use the MTTR and the Mean Time Between Failures, or MTBF, to calculate availability.

How to improve MTTR

To improve the MTTR, you will have to evaluate and try to reduce both variables in the formula. Although, mathematically, reducing the number of repairs won’t reduce the MTTR in itself (if the total reactive maintenance time stays the same), in reality, reducing the total number of repairs is always positive.

How to reduce the total reactive maintenance time

The total maintenance time starts from the minute a failure is detected and only ends once the work order is closed.

✅ Step one: react faster to failures

Start at the very beginning. How much time elapses until the maintenance team is notified? And, afterwards, how long until each task falls into the right technician’s hands?

If that’s where you’re failing, streamline your process. Maintenance teams can’t be everywhere at once, so make it easier for clients to report failures (unbiased hint: use Infraspeak Direct™). Then (again, unbiased hint: use Infraspeak Gear™) assign the task to a technician.

✅ Step two: organise your repairs

Unless it’s your lucky day, you’re probably dealing with several repairs at once. It’s important to organise repairs according to their priority. If you do not have a protocol to assign priority, it’s not too soon.

If you have a diagnosis already, don’t send your technicians without ensuring all the necessary materials and tools are in stock. It sounds obvious, but “haste makes waste” and you want to avoid going back and forth. Check out our article on how to make a perfect work order to make sure technicians have exactly what they need to get started.

💡 Getting a correct diagnosis

- compare what the client reported with previous failures and work orders;

- train staff to make quick checks, or provide remote assistance to troubleshoot problems;

- if you have condition monitoring tools or sensors, it might be possible to make a complete remote diagnosis.

✅ Step three: repair or replace

An excessively high repair time may be a warning sign that certain pieces of equipment should be replaced. If you combine the cost of repairing and the loss of productivity incurred during downtime, is replacing that piece of equipment more economical?

How to reduce the reactive maintenance

Fighting multiple fires at once never helped anybody. Therefore, you want to decrease the number of repairs you are dealing with at once. Reducing the MTTR involves three main factors — accelerating reporting, centralising and organising information, and investing in equipment maintenance.

Again, the secret may lie within your team. If an operator notices that a piece of equipment is underperforming, a service technician should be called immediately. Acting quickly may prevent a complete shutdown. In the case of an emergency, the technical operations manager should be available to give a prompt response and to review the protocol with the team.

Almost all equipment requires periodic revisions (learn everything you need to know about preventive maintenance in our ultimate guide). For heavy-duty machines, actually replacing some mechanical components regularly (often annually) is highly recommended. What you may not know yet is that you can automate these notifications and ensure that all maintenance is up to date using a CMMS or, even better, an Intelligent Maintenance Management Platform.

👷We’ve explored this further in our whitepaper How to Avoid Reactive Maintenance, in which we pointed out 8 concrete ways to reduce the Mean Time to Repair. Download it now!