Maintainability is the easiness, accuracy, and safety with which maintenance tasks are performed after detecting a failure to an asset or equipment. Therefore, to calculate maintainability is to estimate the probability of equipment returning to normal operation after maintenance.

It is an especially important concept in industrial maintenance, but exists in other areas. In the case of software, for instance, we would be referring to the simplicity with which software is fixed after a bug is detected, or the speed with which it is changed to meet new requirements and realities (and we like to think that Infraspeak has good maintainability).

Maintainability vs. Reliability

There are three concepts we need to distinguish in industrial maintenance: maintainability, reliability, and availability. Maintainability, as we said above, is the simplicity in which the assets are repaired. In other words, good maintainability implies repairing failures as quickly as possible.

Reliability is making assets “last” and work for as long as possible. Combining high maintainability with high reliability is what ensures high asset availability – that is, a good percentage of uptime. That’s why reliability-centered-maintenance aims to keep assets functional and available for as long as possible.

How to calculate maintainability

Calculating maintainability is a whole subject in itself. There is no simple formula for calculating maintainability. Since it is a probability, it is an estimate based on other indicators.

1. Mean Time To Repair (MTTR).

The Mean Time to Repair is one of the main metrics of industrial maintenance. Not sure what it is and how to improve it? Here’s our aticle about the MTTR.

MTTR is a good indicator of maintainability by itself. That is, the shorter the MTTR, the more likely you are to restore a damaged asset. Or, if you prefer, the downtime is lower on assets with higher maintainability. If you are guided by this metric, a good standard would be a 5-hour MTTR. A 50H downtime throughout the year should be sufficient for at least 10 failures.

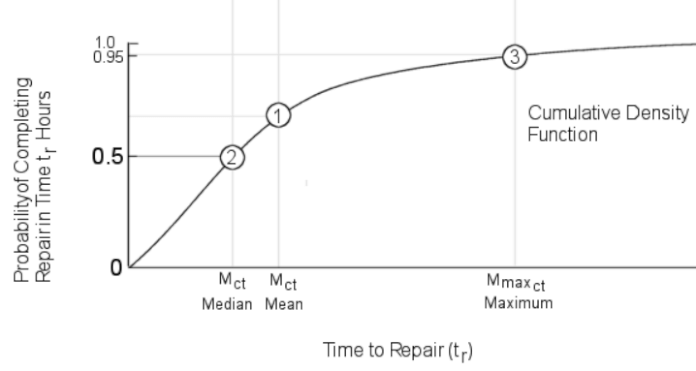

There is also a maintenance function, M(t), which corresponds to the estimated probability of completing a repair in a given period of time. The most common way to calculate is through the log-normal which corresponds to the values associated with MTTR and two other indicators:

Source: Reliability Analytics

2. Median Repair Time

The time required to perform one-half of the repairs (represented by the item no.2 in the graph);

3. Maximum Repair Time

Mmax, which is the maximum time established to complete a certain percentage of all the repairs (e.g. 90% of the repairs should be performed within one hour). You should use real data from your maintenance management software to estimate realistic maximum repair times.

How to improve maintainability

The only way to improve the maintainability of your assets is to start repairing failures faster. Here are 4 ideas on how to do that:

1. Train your team better

The more training you offer your staff – especially new recruits, if your team has a high turnover – the faster they will act. Encourage teamwork and bring all your coaches together around a common goal, rather than just focusing on individual performance.

2. Concentrate more information on each asset

Try to concentrate all information about the asset and repair tasks. This takes maintenance staff less time to figure out what they have to do and which tools they may need. Preferably, do this using software or an app so they can access that information anywhere.

3. Purchase similar equipment

Another way to save time in repairs is to purchase similar equipment, as airlines do. On the one hand, the staff will become familiar with all the equipment; on the other, the equipment is likely to be compatible with several pieces of equipment which make stock management easier.

4. Increase planned maintenance

When we talk about industrial maintenance, reactive maintenance almost always implies long downtime periods. Therefore, one of the best strategies you can adopt to increase maintainability is to increase the percentage of preventive maintenance (more specifically, it should make up 90% or more of the total).

Not even the best maintenance manager can prevent all breakdowns. But, when they do, ensuring good equipment is the only way to avoid unnecessary downtime.

If you are having trouble collecting the data that would allow you to optimise your maintenance plan, talk to our experts to find out how the Infraspeak platform can help you.