In today’s competitive world, with stakes higher than ever, facilities and maintenance managers strive to achieve near-zero downtime, operational efficiency and return on investment.

Technology is steadily emerging as our only tool to cope with more sophisticated buildings and more rigorous health and safety regulations. This technology can collect and store data for us, but also interact with others to automate task flows and optimise our limited resources. The end result is more time to make the big calls.

Infraspeak’s integration with Siemens Desigo™ CC connects facilities, assets, data, and teams, guiding your business into the age of intelligence.

About Desigo™ CC, Siemens’ Building Management System (BMS)

Siemens’ Desigo™ CC software is a BMS which specialises in task automation for high-performance buildings. It was developed for comfortable, safe and efficient facilities and is easily scalable — covering simple single-discipline systems and complex, fully integrated buildings. A BMS like Siemens Desigo™ CC is the perfect tool for controlling electrical and mechanical equipment in your building, remotely and in real time.

It allows off-site staff to centrally control ventilation, lighting, fire security systems, security alarms and more. Furthermore, real-time monitoring allows for instant detection of changes of performance, whilst in-built reports and analytics functionalities aid decision-making.

However, it’s not always simple for companies to extract the full value of this data because it’s spread across multiple silos that do not interact. Is there an easy solution, though?

You bet there is! You should use an intelligent maintenance management platforms (IMMP) like Infraspeak.

Why integrate maintenance and building management systems?

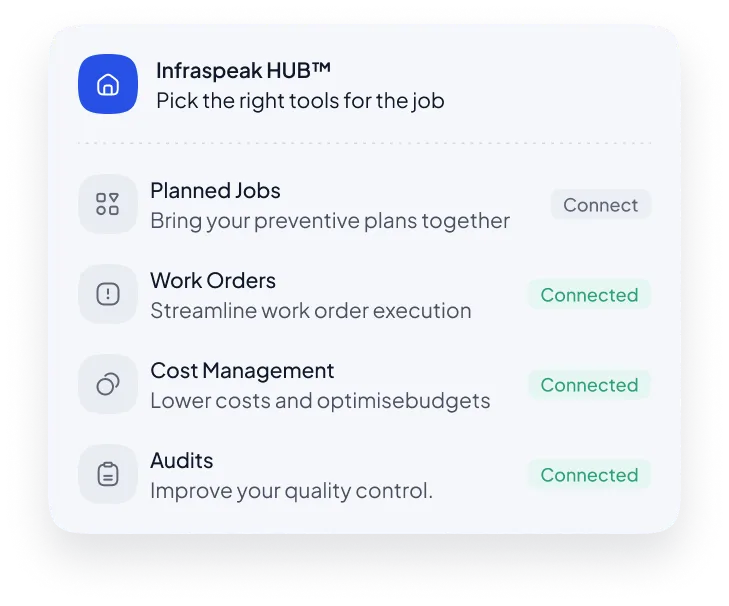

Infraspeak can collect information from several formats and platforms and process it all in near real-time from one dashboard.

Integrating an Intelligent Maintenance Management Platform with a BMS has many benefits as it gives facilities and maintenance managers a holistic view of both the building and the assets within it.

The two work in harmony, centralising all necessary information related to the operation to help facilities and maintenance teams draw better conclusions on how to operate more efficiently.

Far easier than juggling several systems throughout the day, this integration allows maintenance teams to work faster using just one central dashboard.

Additionally, integrations like this between a BMS and IMMP speed up several processes. One example is the creation of work orders. With everything connected, contractors or in-house workers are notified when an alarm is raised by the BMS, and only start work when necessary. This cuts unnecessary maintenance.

Another key benefit to this integration is that as more data is collected (equipment history, maintenance logs, statistics etc), it becomes increasingly easy to identify patterns, spikes and outlying data points, meaning you can learn about your operation today, and plan for tomorrow. Infraspeak then steps in and mines that data to crunch it into intelligent suggestions, alerts, and task automation. This improves operational efficiency but also contributes to and improves the data loop.

Integrating Infraspeak with Siemens Desigo™ CC

By combining Siemens’ advanced building asset monitoring capability with Infraspeak’s holistic maintenance management suite, you gain a truly comprehensive solution which decreases overhead costs and wait times on breakdowns.

Key information for maintenance and energy management, namely temperature readings and uptime measurements, are collated in real-time to simplify data collection processes.

Data collected by Siemens Desigo™ CC is shared with Infraspeak meaning that whenever an asset faces a potential issue, it is flagged, before a work order is automatically created, helping you to meet pre-defined SLAs.

How does the workflow operate?

- Asset measurements monitored by Siemens Desigo™ CC are integrated with Infraspeak.

- Infraspeak creates automatic corrective work orders when:

- asset maintenance alarms are triggered (reminders to change air filters, abnormal machine temperature, etc.)

- energy consumption is above X level;

- number of working hours above Y.

Key benefits

Infraspeak’s integration with Siemens Desigo™ CC connects facilities, assets, data, and teams.

- Preventive and corrective actions are immediately created and assigned using data intelligence and automation.

- The reaction time of the team is reduced thanks to real-time asset monitoring and data synchronisation.

- The maintenance team can complete all their work using just one dashboard.

- An efficient operation allows building managers to save considerably as it cuts out unnecessary maintenance interventions.

How do you activate this integration?

Integrating a maintenance system with external software is no longer a mammoth task. The protocols of standardised data exchange and cloud computing have made this type of integration possible in — literally — five minutes, with both systems always kept up to date.

However, it is something that requires planning. That’s why, if you are an Infraspeak customer and are interested in this integration, get in touch with your Customer Success Manager. They will help you to identify what information you need from the external software to support your maintenance operations on Infraspeak and which operational data is important for the platform to be integrated.

Still not an Infraspeak customer? Book a personalised demo of our Intelligent Maintenance Management Platform (IMMP) and discover how we can help your operation.

- Eliminate potential safety hazards.

- Improve SLA completion rate by up to 91%.

- 100% compliance with regulations for maintenance operations.