What is an IMMP or Intelligent Maintenance Management Platform?

IMMP means Intelligent Maintenance Management Platform, and it’s the latest technology available to maintenance managers.

Like the name itself suggests, these platforms combine maintenance management with artificial intelligence (AI) to collect equipment data and turn it into valuable insights.

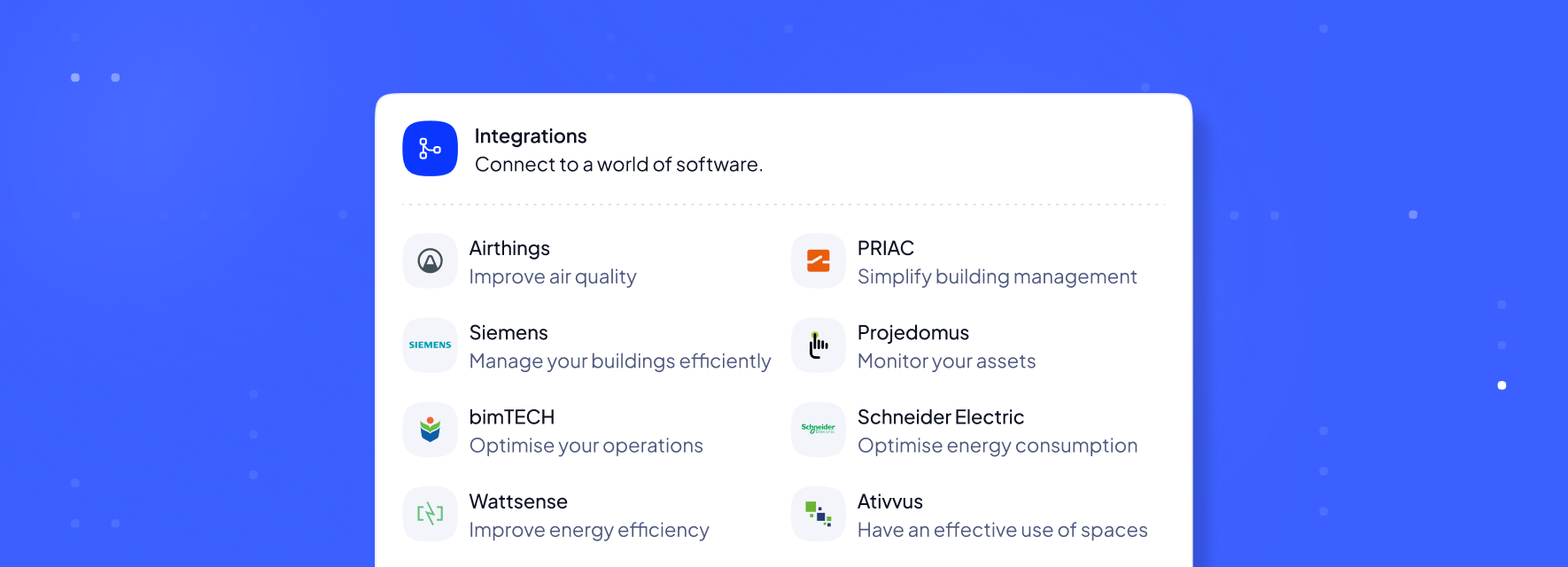

As to why they’re called platforms rather than maintenance software, it’s because they can integrate other tools, making it a vibrant, live maintenance system instead of a static bubble.

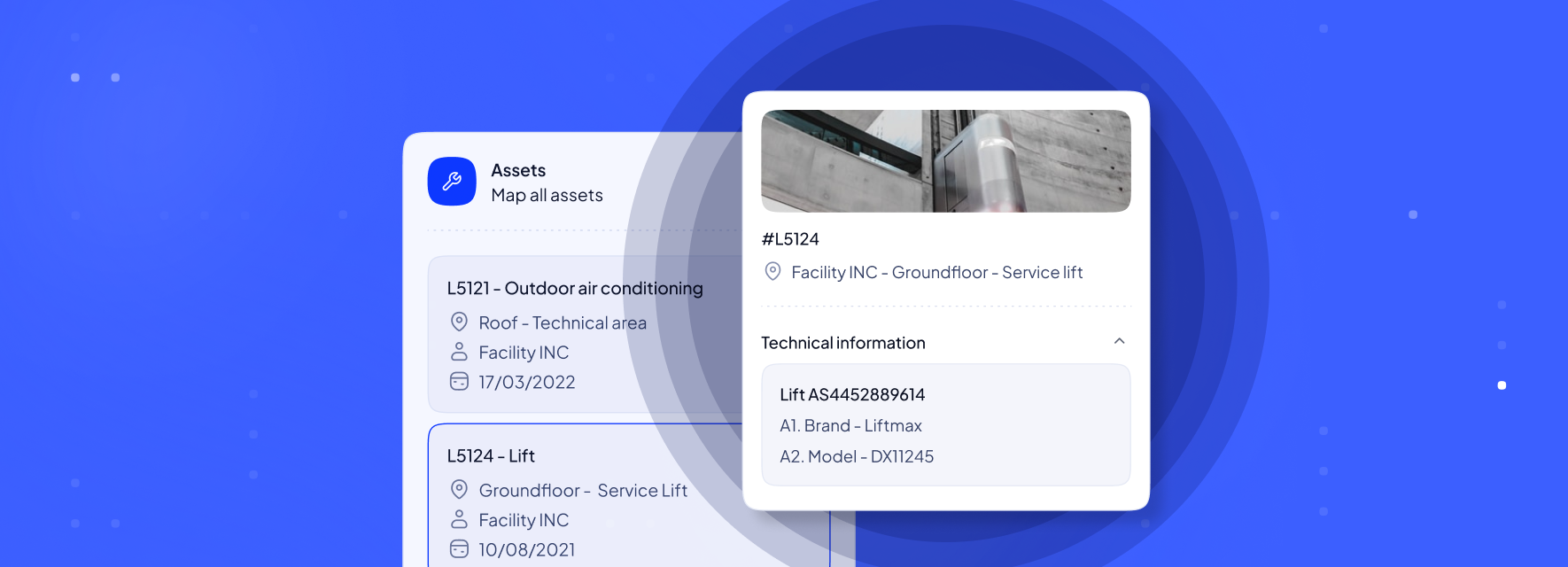

An IMMP is, therefore, a flexible, intelligent ecosystem of fully connected apps and hardware that makes your whole maintenance operation — people, buildings, assets, software, IoT hardware — communicate and work together. As such, it is capable of leveraging (better) data to automate tasks, make smart and time-saving predictions and enable all kinds of maintenance operations for a whole decade.

How did we get here?

Starting in the 80s, companies began to develop “downtime intolerance”. There were significant efforts to achieve more reliability, quality and safety, which paved the way for reliability-centred maintenance. At the same time, in the West there was a growing interest in the Japanese Economic Miracle of the previous decades, which was attributed, among other things, to lean manufacturing.

At this point and till the 2000s, maintenance managers started to rely heavily on Excel sheets. The love affair with corrective maintenance was effectively over, and what followed was a long-standing, happy marriage with preventive maintenance. Competitiveness required greater control and less downtime, and new ISOs were released. The famous ISO 9000 dates from 1987.

Afterwards, Excel was slowly replaced with Computerised Maintenance Management Systems (thankfully shortened to CMMS). They were definitely an improvement and enabled businesses to track more data to control their operations. However, with the dawn of Industry 5.0 (and Maintenance 5.0!), this technology began to feel somewhat lacking. Cue in: Intelligent Maintenance Management Platforms (IMMP).

Differences between a CMMS and an IMMP

Don’t take this the wrong way. When CMMS first appeared, it was a revolution. They stored data, which made it easier to register logs and asset history, even if the Microsoft Access-based CMMS of the early 90s were incredibly hard to update. Towards the end of the decade, they transitioned to local servers, and in the early 2000s browser-hosted versions became available.

Finally, in the 2010s, cloud-based CMMSes went mainstream. This was a more adequate and mobile-friendly solution for the modern world. And most generated reports automatically, which put maintenance managers on the right track with data-driven decisions. However, at the end of the day, they weren’t much more than a system of records. At their core, they never stopped being a database.

Besides, with the rise of IoT in the last few years, managers need a system that truly is, well, a system. Why should maintenance or asset management be an isolated system within your operation? Isn’t that counter-intuitive and counter-productive? Any maintenance software should integrate with other tools, which is why we like to say platforms are akin to an “ecosystem”.

When you take these two factors in – processing data and connectivity – it becomes clear the Intelligent Maintenance Management Platforms emerge as maintenance’s way of advancing further into Maintenance 5.0 and responding to the challenges in the short and medium-term.

📝 Suggested reading: Why facility managers are moving on from CMMS

An Intelligent Maintenance Management Platform (like Infraspeak) differs from a CMMS in two ways:

- Its “platform” status;

- Its intelligence.

1. More than software, a platform

Intelligent Maintenance Management Platforms are platforms (surprise!) by design — they’re made to be a whole ecosystem of resources (software and hardware) to help maintenance managers streamline their operations through with outstanding flexibility, intelligence and connectivity.

A CMMS’s functionality is given by its own set of features, which may be more or less appealing to you depending on the software and your operation. Meanwhile, an IMMP has the ability to connect and fully integrate with external tools and resources that your maintenance teams need to work in a simpler, more intelligent way.

Besides a multitude of native apps, an Intelligent Maintenance Management Platform can seamlessly integrate with external software — such as ERP, CRM, invoicing software and even custom software —, as well as hardware such as NFC tags, sensors, and all kinds of IoT.

2. Intelligence and automation

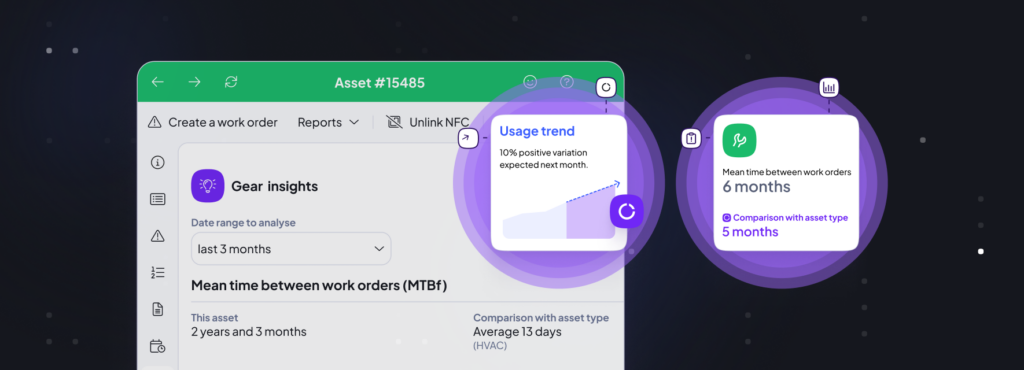

While the main value of a CMMS is to centralise information and manage tasks, an IMMP goes a few steps further. It leverages all that data to automate tasks and provide you with smart insights, time-saving predictions and suggestions.

Any time you connect a new app to your IMMP, the whole platform is enhanced. Previously connected apps gain new features so the whole system is fully integrated, and your existing records gain new information and new functionality.

This makes Intelligent Maintenance Management Platforms extremely flexible solutions, as they allow you to connect with whatever tools fit the needs of your team and your operation.

This means that an IMMP can evolve with your business over time. For the next 10 years, you won’t need to jump to another solution because the complexity of your operations has increased, and you won’t have to lose whatever information you had recorded so far. Need more stuff? Simply connect more stuff and integrate some more.

Benefits of an Intelligent Maintenance Management Platform

No two operations are the same. In other words, the benefits you’ll reap from any maintenance system vary according to the challenges you face. The good thing is that, unlike a CMMS, an IMMP acknowledges this. Instead of “one solution fits all”, you’ll get a flexible platform that can take any shape you need it to. That is why we feel comfortable saying everyone will enjoy these six benefits:

It saves time

Arguably, one of the biggest benefits is saving time. Because AI automates workflows, you’ll spend much less time planning maintenance schedules. Also, managers only need to validate intelligent suggestions (such as specific suppliers, materials, or assets for certain failures) to set everything in motion and start repairs. If you’re curious about how this works, check out our own Infraspeak Gear™.

It adapts to your operations

We already mentioned this above. Unlike regular CMMS, IMMPs can integrate different apps, other tools or software, and hardware. This means you can choose the features that best suit your operations, and finally integrate maintenance and facility management with the whole operation. Plus, the more you integrate, the more data you’ll collect for the system to process.

It improves control

When you’re busy browsing through all of the data and keeping an eye on two or three different dashboards, you’re bound to miss something. That’s why IMMP’s increased connectivity and automation provides more control over operations. You can monitor schedules, where your team members are, sort tasks, assign tasks and suppliers, keep track of your maintenance spending, etc., all in one place.

It avoids non-compliances

Also related to improved control, an IMMP makes it easier to track standards, regulations, and SLAs. The platform will notify you when a deadline is coming up and provide intelligent alerts when there isn’t a plan assigned to an asset. If you’re struggling with meeting standards and avoiding non-compliance, an IMMP will make you feel like you’re operating on steroids.

It sets priorities

Maintenance managers struggle with the trade-off between cost and risk: performing preventive maintenance or waiting for a failure to happen, whether to repair or replace and where to invest in. But when intelligent maintenance systems become the one source of information and data, it’s easier to keep track of criticality and monitor real-time conditions, which leads to continuous cost-based prioritisation.

It enables predictive maintenance

Predictive and condition-based maintenance are at the heart of Maintenance 5.0 and lean, but it’s only efficient if the equipment is connected to a central system. Otherwise, technicians will spend too much time monitoring equipment and registering data – and that’s the opposite of what we’re looking for. The flexibility of IMMPs, combined with intelligent suggestions, is one step forward.

Who can use an Intelligent Maintenance Management Platform?

Generally speaking, any company whose operation improved with a CMMS or Enterprise Asset Management (EAM) can also benefit from an IMMP. That includes those with large infrastructures, such as factories, plants, office buildings, hotels, chain stores, shopping centres, and hospitals. Intelligent suggestions and integrations improve control and eliminate “blind spots” for managers.

IMMPs are also useful for technical assistance, namely third-party providers with an extensive asset portfolio spread across different locations. In this case, mobile apps are especially helpful to connect field teams, giving technicians access to all the support data and documents they need, and even monitoring location through GPS coordinates.

- Are you responsible for large facilities or infrastructures?

- Do you need to comply with quality, safety, and hygiene standards?

- Are you having trouble complying with all the SLAs you agreed to?

- Do you think it’s hard to make data-driven decisions?

- Do you manage a large field team that needs to act fast 24/7?

If you answered “yes” to any of these questions, you should definitely proceed and learn more about IMMPs.

⚙️Curious? Find out how Infraspeak’s Intelligent Maintenance Management Platform will help you transform your operations today. Book a free product tour with one of our specialists!