“Maintenance takes forever to get here and fix problems.”

To which maintenance managers reply, “Nobody warns us when something fails.”

Anyone who works in Maintenance and Operations has overheard something like that. Along with other classics, such as “equipment is always down” and “we never know if service has been reestablished”, the accusations go back and forth. But, come to think of it, most of the problems you face in your day to day are avoidable. Find the common denominator:

- Do you take too long to react to equipment breakdowns?

- Do technicians struggle to understand what they have to do?

- Do your clients call a lot to know what is happening at their facilities?

- Do you often delay repairs because you run out of inventory?

It all comes down to a lack of communication. They say communication is key to relationships, and so far we have not found an exception to the rule. The twist with facilities management is that there isn’t a single flow of information. First, there is the one between clients and service providers; then, from managers to technicians; and finally from managers to suppliers.

If you’re a service provider, you have to manage all three. There’s only one way to do it, which is centralising information in one source. Your facilities management platform should provide online monitoring, messaging, and real-time notifications. This will align the three communication flows with workflows, which avoids noise and bottlenecks. Here are a few examples of how you can solve the issues we mentioned before:

- Staff can create maintenance requests through the platform, which connects them directly to maintenance teams;

- You can attach standard procedures to work orders and store maintenance logs in the cloud, so that technicians always know what to do;

- Online monitoring means that both clients and managers can follow the status of each work order;

- Inventory can be deducted automatically from your stockroom, which avoids understocking.

In a 2012 report, when social technologies were booming, McKinsey found they raised productivity by 20 to 25%. In maintenance, you can clearly see how it lowers MTTR. From the minute a client reports a failure, technicians can get started, receive all the information they need, solve the problem, and save the day. Even delays due to lack of inventory are avoidable.

Communication & client management

However, it would be silly to think communication doesn’t go beyond “technical” benefits. Communication is pivotal to increase transparency and improve client management, which is something that can “make or break” your business. When you combine efficient communication with the best technology, it’s easier to manage expectations, show compliance and gain your client’s trust.

Even in B2B, clients don’t value just the rational factors — which you can also frame through effective communication — but also emotional ones. According to the Harvard Business Review, there are other elements of value, such as the ease of doing business, individual values (such as aesthetics or perks) and inspirational values (such as enhancing the company’s social responsibility, hope and vision).

You need to assume that more service providers can offer the same level of service. Other companies will practice similar prices, follow the same standards, and even achieve the same performance indicators. Therefore, other elements of value are often tie-breakers and lead to customer loyalty. Poor communication is a major weakness, and it can quickly compromise a working relationship. Good communication leaves everyone on the same page — no guesswork, no drama.

Even when disagreement occurs (like a missed deadline), honest communication will turn the tension into solutions. This is client management in action — listening to concerns and proving reliability.

In facilities management, how you communicate decides whether clients stay loyal or walk away.

Communication & employee retention

On the home front, great communication creates team spirit and helps with employee retention. Workers need to feel appreciated and understand what is driving managerial decisions. Otherwise, they will quickly feel disengaged with work, which makes them more likely to quit and, according to a Gallup poll, engaged employees also have 70% fewer safety accidents.

Managers are often pinpointed as the culprits of poor communication. Among other things, employees accuse them of not recognising their strengths, withholding information, micromanaging, failing to listen, and not having “their backs”. Another 2015 Gallup study found that employees were three times more likely to be engaged with their work when managers hold regular meetings.

Studies show that effective communication increases employee retention by 4.5x longer than those that don’t. Why? The reason is that 63% of employees say they’ll work harder if their firm makes them feel seen and heard.

Despite all of these benefits, keep in mind that communication needs to be purposeful. Over-communication may drive your employees to quit (and is equally frustrating for your busy suppliers). A study conducted during lockdown found that 44% of employees craved a workday without video calls, 31% wanted a break from emails, and 25% wished for a notification-free day. Ouch.

Communication & supplier relationships

Sure: you’re a client, so suppliers will always be patient with you. However, you are much more likely to build a strong relationship with effective communication. Mutual respect is the first step to getting on your supplier’s good side and getting them to go the extra mile to sort something out for you. Take the time to learn how they work, explain what you’re planning, and start a two-way conversation.

If you are subcontracting, be open and transparent about the intentions and goals of the project. Communication will make way for trust, and that is how you solve problems together. If you are ordering parts, be reasonable about lead times, deliveries, prices, and requirements. It may sound clichéd, but treat your suppliers the way you like your clients to treat you.

Solid supplier relationships are beyond emails — it’s about keeping buildings running without hiccups. Without communication, delays or mistakes can shut down operations for days or even leave security systems broken. But when you set clear expectations (like exactly when parts should arrive) and update each other in real time, everyone will win.

Strategies for effective communication in facilities management

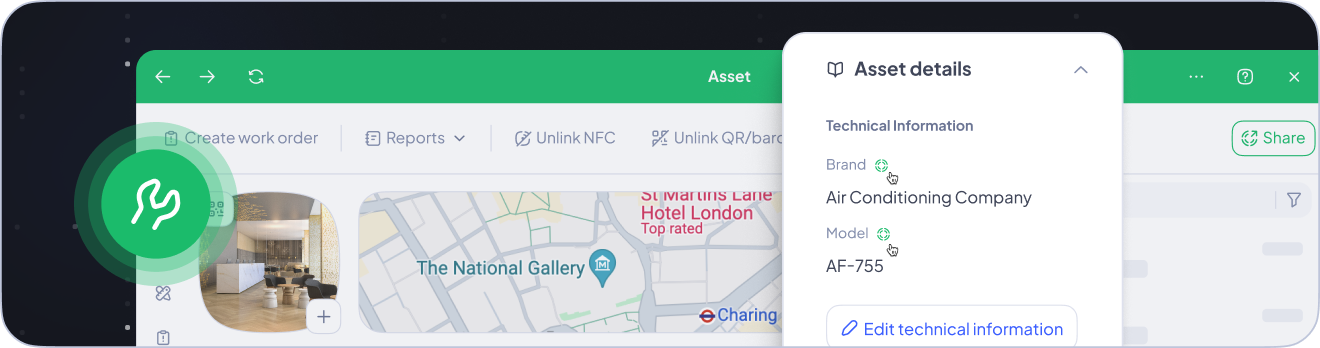

- Centralise information: Use a collaborative facilities management system like Infraspeak to store all updates, repair logs, and schedules. If everything is in one place, your team doesn’t have to comb through emails for information.

- Regular updates: Schedule meetings to review progress and plan. It could be a 10-minute team huddle every Monday. Ask: “What’s stuck? What’s next?” Fix small issues before they ruin your week.

- Document processes: Document all procedures and assign responsibilities in your system.

- Automate workflows: Leverage automated alerts and task assignments within the software to streamline communication and ensure timely responses to requests and emergencies.

- Feedback and continuous improvement: Encourage team members to provide feedback through integrated feedback tools or surveys. Use this input to refine processes and address any gaps in communication.

- Training and onboarding: Train all staff on the communication protocols and tools. Regular training sessions keep everyone updated on new features.

📖 Step up your game further with this article on how to clearly communicate with employees.

A collaborative FM platform to end communication silos and foster a feedback culture

Enhanced scalability

Collaborative platforms simplify scaling by standardising workflows. When adding new teams, locations, or clients, everyone plugs into the same system immediately. Then, they can access historical data, protocols, and communication tools.

Compliance and audits made easy

These facilities management platforms automatically track every action, update, and conversation. This process creates a clear audit trail, and industries like healthcare or manufacturing can instantly prove compliance during inspections.

Imagine a safety inspector asking for fire alarm records: managers pull up exact details — who tested it, when, and what feedback was noted — in seconds.

No more lost knowledge

When employees leave, their expertise doesn’t vanish. Centralised platforms store institutional knowledge— like how to troubleshoot old equipment or handle new client requests.

New hires can look into past work orders, guides, and feedback logs, reducing reliance on a few “gatekeepers” of information.

Sustainability reporting

Facility managers use sustainable facilities management tools to track energy use, waste patterns, and maintenance schedules.

For instance, analysing water waste data might reveal peak usage hours, sparking collaborations to fix leaks or adjust workflows. Even suppliers can get involved in aligning deliveries with goals like recyclable packaging.

Custom reports

Infraspeak can generate tailored reports for executives (high-level efficiency stats), technicians (pending tasks), or clients (service summaries). Everyone gets the insights they need without wasting time on busy work.

Modern collaborative platforms empower facilities managers to customise workflows, thus breaking down communication barriers.